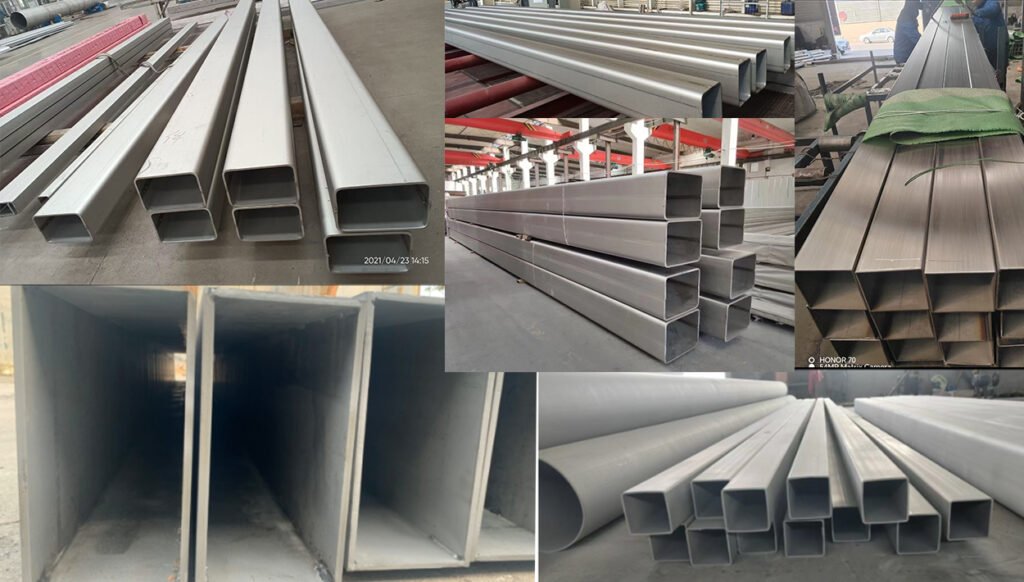

SHIWANG STEEL PIPE is a leading manufacturer of SAW (Submerged Arc Welded) stainless steel pipes, with a strong focus on large-diameter, heavy-wall straight seam welded pipes. Our advanced welding technology and rigorous quality systems ensure unmatched strength, corrosion resistance, and performance in demanding industrial applications.

Product Name | Longitudinal Submerged Arc Welded (LSAW) Stainless Steel Pipe |

|

Brand | SHIWANG STEEL PIPE |

|

Material Grade | AISI 304 / 304L / 316 / 316L / Duplex / Custom |

|

Standards | ASME B36.10M / B36.19M, ASTM A358 / A778 / A999 |

|

Welding Method | SAW – Submerged Arc Welding (Single or Double-sided) |

|

Outer Diameter | 8” – 64” (219mm – 1625mm) |

|

Wall Thickness | 5mm – 70mm |

|

Length | Up to 13m, custom lengths available |

|

Finish | Pickled, Polished, Brushed (as required) |

|

Ends | Beveled / Plain / Flanged |

|

Plate Cutting – High-quality stainless steel plates are cut precisely to required width.

Edge Milling – Plate edges are prepared for consistent welding quality.

Forming – Plates are formed into round pipes via UOE or JCOE method (as per order).

Submerged Arc Welding – Internal and external welds completed using advanced SAW technology.

Heat Treatment – Solution annealing and stress-relief processes to ensure pipe durability.

Weld Seam Inspection – 100% NDT (X-ray, UT) for seam reliability.

Hydro Testing & Final Inspection – Pressure tests and dimensional verification per standard.